BSS Couplers – FT Series from F-Tive’s, are parallel-threaded splice systems that assure, providing continuity and structural integrity to reinforced concrete complying with the requirements of MS146: 2014 Grade B500B. FT Series spliced rebars behave as continuous lengths of rebars by providing “full strength” intension, compression and stress reversal applications.

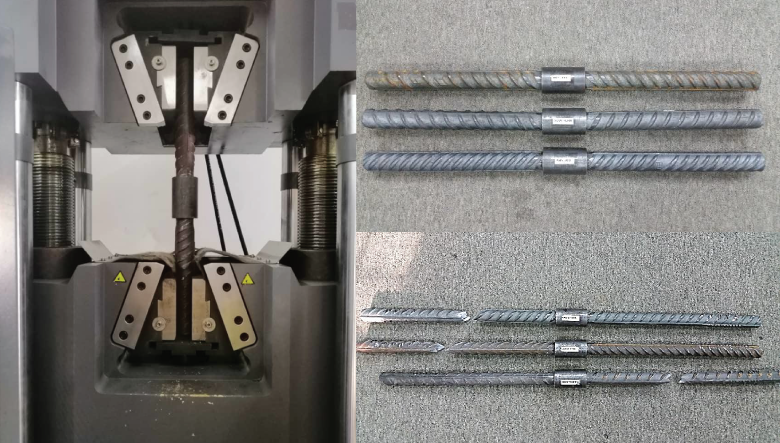

Destruction Results

FT Series Threaded Rebar and BBS Coupler are jointed together

1) Tensile Test

2) Elongation Test

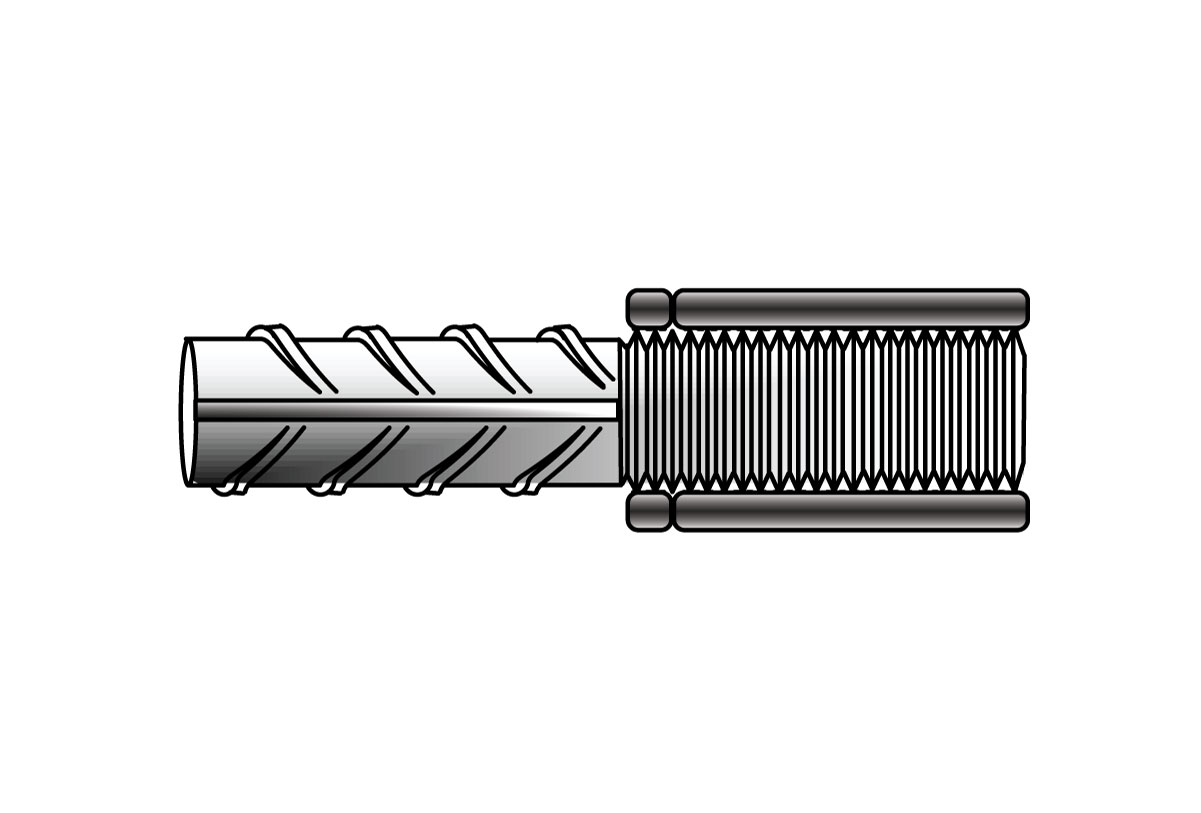

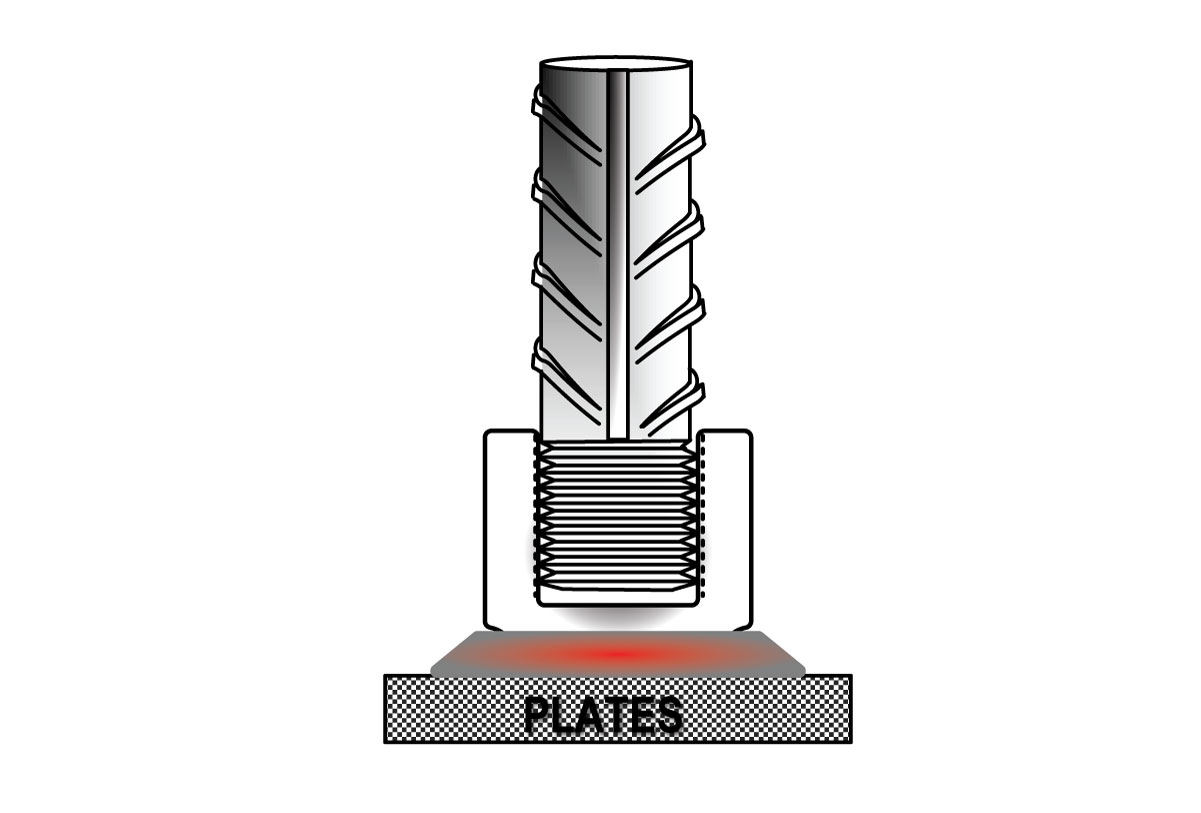

Protruding Threaded Rebars

BSS COUPLER

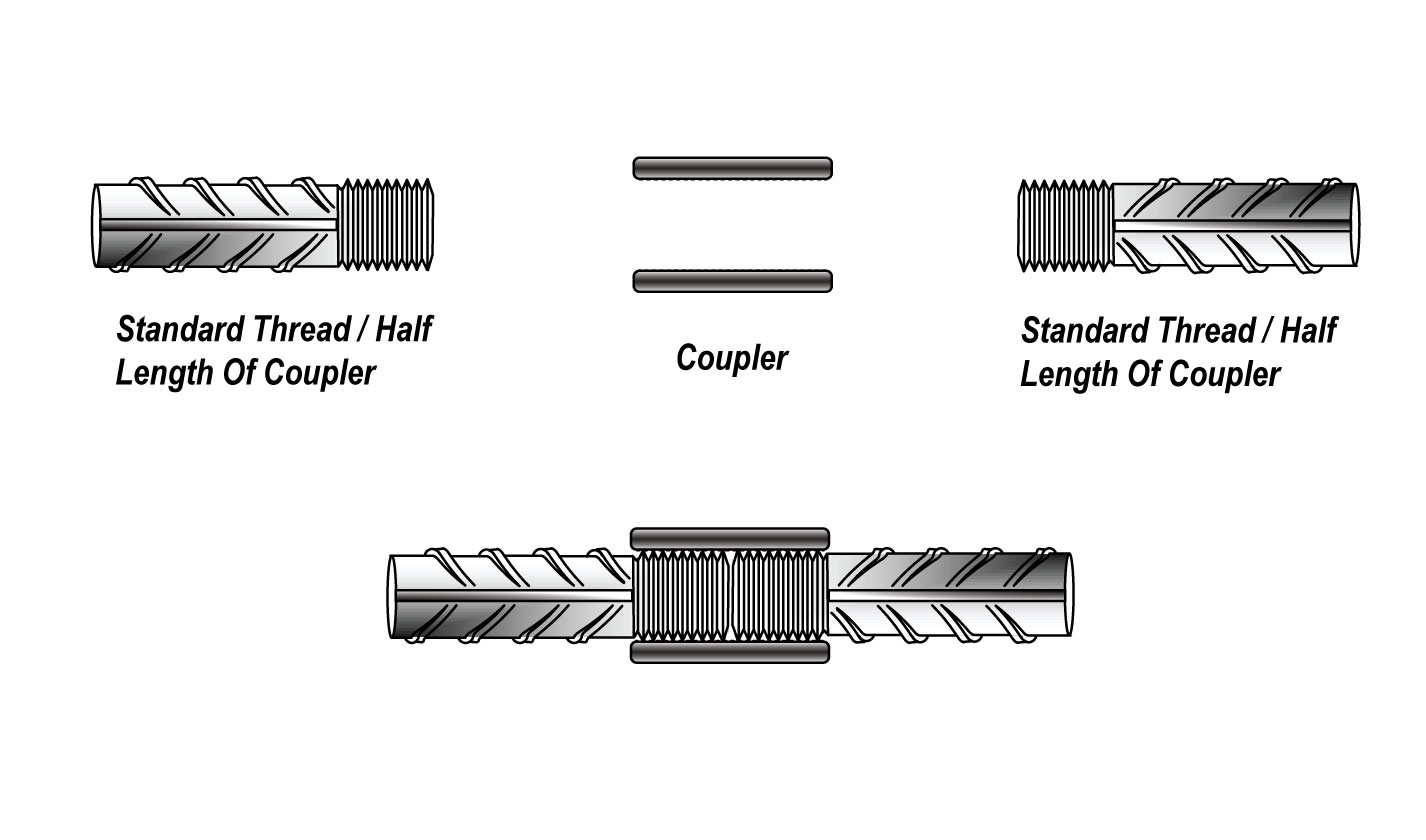

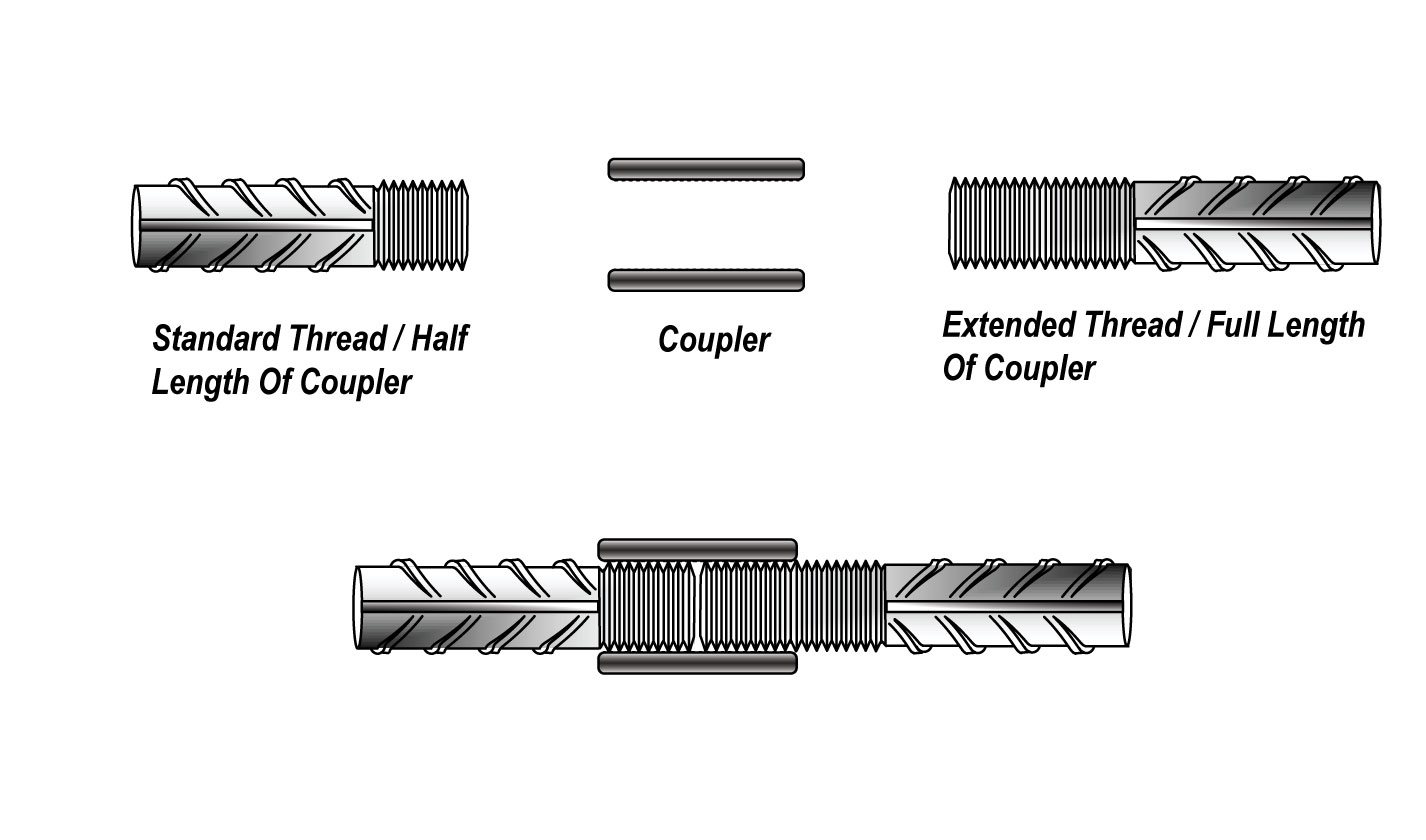

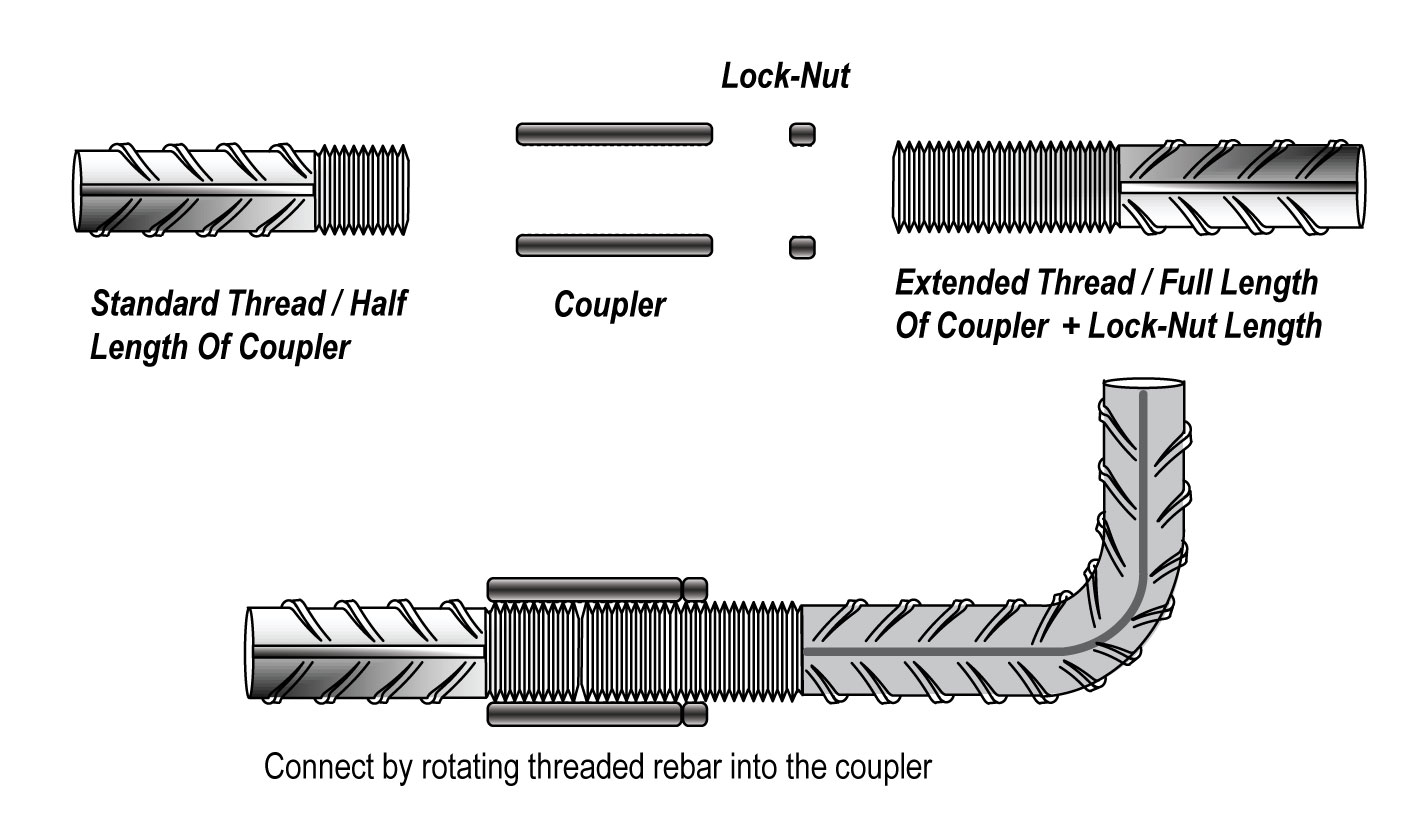

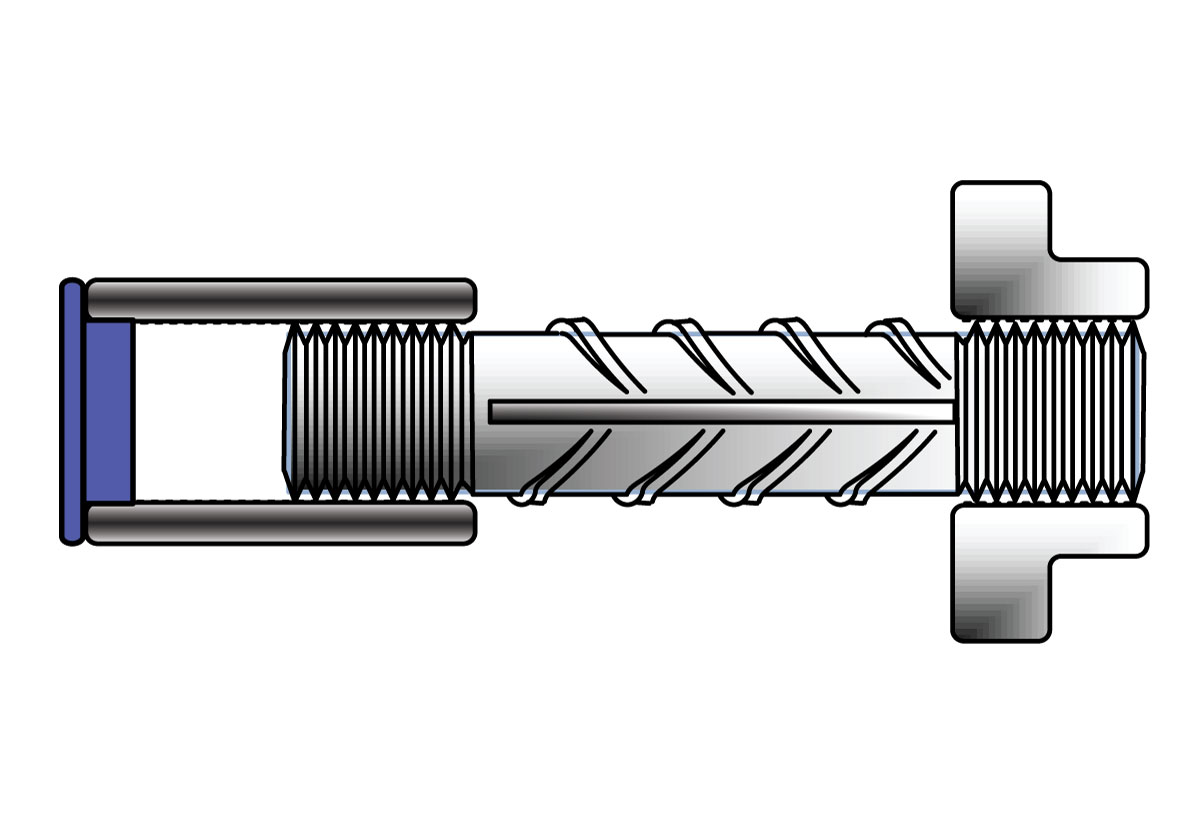

The Unique Parallel-Thread Design

The BSS Couplers High system, Safety, Parallel-Threaded design provides ease of installation, consistent performance and durability. It also has higher tensile strength than lap splicing and provides full load transfer with the slimmest and shortest coupler possible.

For applications where couplers need to be cast in the concrete. BSS protection PE End-Cap keeps the couplers free from concrete or grout debris. All FT Series threaded rebars are protected by a PE End-Cap to prevent thread damage during transportation and handling.

BBS Couplers Yield Tensile Strength

are stronger than the rebars.

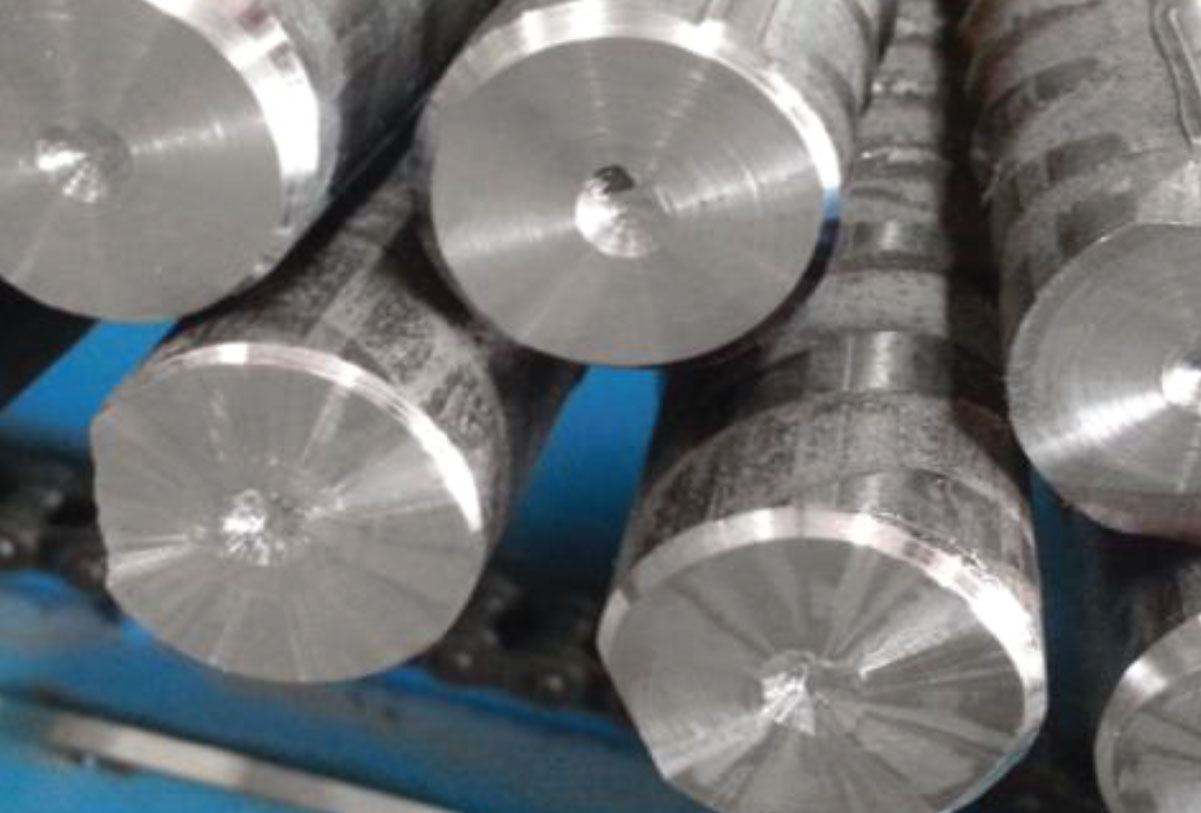

BBS Couplers Were Developed

for the coupling, any length of rebars for T10mm to T50mm.

BBS Couplers Connection System

is available in many different variations, like for example: Standard Couplers, Reducer Coupler, Weldable Couplers, Terminator Couplers, etc.

Splice Method